Expert in high temperature insulating technical felts

Apronor >

Apronor offers high temperature insulating technical felts. The fibers used for their manufacture are chosen with care, according to their properties.

Resistant to high temperatures, these technical textiles provide excellent insulation (thermal, acoustic, etc.). Applications vary by product, as do density and thickness. But all are characterized by their heat resistance and the protection they offer. Likewise, most of our felts are available in several references. You therefore benefit from a wide range of insulating textiles.

Technical felts

Apronor technical felts (glass and silica needle felts, papers, webs and loose fibers) are very good insulators due to their specific composition. They are intended for applications in high temperature conditions.

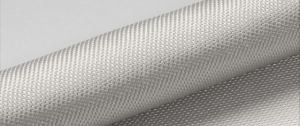

Glass and silica needle felt

Apronor technical felts (glass and silica needle felts, papers, webs and loose fibers) are very good insulators due to their specific composition. They are intended for applications in high temperature conditions.

- Vibration reduction

- Very good mechanical resistance

- High temperature resistance

- Excellent thermal insulation

- Thermal insulation

- Soundproofing

- Filtration

- Boiler compensator

- Filtration fields

- Smoke purification

- Dust recycling in industries

- Can be used in various heat sources

Composition: Fiberglass

| Reference | Weight (g/ m²) | Density (kg/m³) | Thickness (mm) | Roll Length (ml) | Photo |

| FAV450/4 | 450 +/-10 | 110 | 4 +/- 1 | 50 | |

| FAV800/6 | 800 +/-10 | 130 | 6+/- 1 | 50 | |

| FAV1300-10 | 1300 +/-10 | 130 | 10+/- 1 | 30 | |

| FAV1600/12 | 1600 +/-10 | 130 | 12 +/- 2 | 20 | |

| FAV3300/25 | 3300 +/-10 | 130 | 25 +/- 3 | 20 |

Needle felt is a very good insulator, the thermal conductivity of which is very low. It is available in several thicknesses and densities. Due to the needling process, the mechanical strength is very good. There is no binder so very little smoke is released. Needled mats are nonwoven textiles made with textile fibers held together by their individual adhesion, which is consolidated by mechanical methods.

SPECIFICATIONS

- Standard width: 100 cm

- Thickness: 5-25 mm

- Weight (g/m²) : 500 – 4500

- Cut pieces: the glass or silica needle felt can be delivered cut according to your plans.

| Temperatures °C | 50 | 100 | 200 | 300 | 350 | 400 | 450 | 500 |

| Thermal conductivity W/m°K | 0,037 | 0,042 | 0,054 | 0,064 | 0,076 | 0,084 | 0,093 | 0,102 |

The silica needle felts are composed of needled silica fibers which guarantees good resistance to extreme temperatures up to 1000 ° C.

Composition : Silica fiber

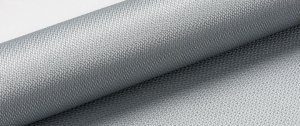

Glass nonwovens

Glass nonwovens are chemically inert, non-toxic felts used in a variety of applications. These include the production of preforms, bituminous membrane reinforcement, mineral insulation surfacing, etc.

- Thermal insulation, insulation and sound absorption

- Reinforcement of composite materials

- Shock absorption

- Insulation surfacing

- Acoustic thermal insulation

- Insulation and sound absorption

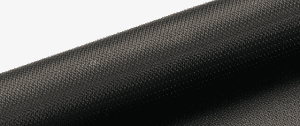

Welding Black® Needle Felt

Welding Black® felt is made from high performance technical fibers. It is used in various fields where effective resistance against fire and heat is required.

- Won’t burn, melt, soften or run

- Excellent fire resistance

- High temperature resistance

- Effective protection against fire and heat

- Fire barrier for seat

- Welding protection blanket

- Passive fire protection

Biosoluble fibers

Bio-soluble fiber is a low biopersistence fiber composed of calcium, magnesium and silicate. Its composition gives it excellent thermal resistance associated with traditional fibrous insulating materials.

Biosoluble fibers

Bio-soluble fiber is a low biopersistence fiber composed of calcium, magnesium and silicate. Its composition gives it excellent thermal resistance associated with traditional fibrous insulating materials.

- No harm to human health

- Good thermal performance

- Low density

- Ease of processing

- Impact resistance

- Reactor thermal insulation pipe

- High temperature gas filtration

- Protection of industrial furnaces and heating equipment

SPECIFICATIONS

- Color: bluish white

- Classification temperature: 1200°C

- Melting point: > 1330°C

- Fiber diameter (avg.): 3.2 microns

- Density (nominal)*: 150 kg/m3

- Tensile strength*: > 250 kPa

*calculated without compression

| Thickness | 1 mm | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| Lenght | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) |

| 610 mm | 122 | 60 | 35 | 25 | 20 | 15 |

| 1000 mm | 380 | 1890 | 110 | 85 | 60 | 45 |

| 1 260 mm | 380 | 180 | 110 | 85 | 60 | 45 |

Papers

Our paper is made from biosoluble fiber in a non-woven matrix. With an optimal content, the paper has excellent thermal and acoustic characteristics. The bio-soluble paper provides great flexibility and resists tearing.

- Resistance to chemical attack

- High temperature stability (up to 1200°C)

- Good resistance to handling

- Excellent flexibility

- Good acoustic and thermal insulation

- Laminating

- High temperature application seal

- Aluminum casting and fabrication

- Heat shield

SPECIFICATIONS

- Color: white

- Classification temperature: 1200°C

- Fiber diameter (avg.): 3.2 microns (avg.)

- Density (nominale)*: 64, 96, 128 et 160 kg/m3

- Tensile strength (128 kg/m3) : 90 kPa

* calculated without compression

| Lenght (mm) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) |

| 610 | 122 | 60 | 35 | 25 | 20 | 15 |

| 1000 | 380 | 1890 | 110 | 85 | 60 | 45 |

| 1 260 | 380 | 180 | 110 | 85 | 60 | 45 |

Blankets

The APRONOR blanket is a needled, flexible, strong and lightweight blanket made from biosoluble fibers. It has excellent thermal insulation and is characterized by its very high temperature insulation performance up to 1200°C.

- High temperature stability (up to 1200°C)

- Excellent resistance to handling

- Soft to the touch

- Low content of infibrates

- Very good flexibility

- Excellent sound absorption possibilities

- Internal coating of industrial boilers

- Heat shields

- Pipe insulation

- Coating for annealing furnaces

- Insulation of domestic boilers

- Aluminum transfer covers

- Controlled cooling of foundry parts

SPECIFICATIONS

- Color: white

- Classification temperature: 1200°C

- Fiber diameter (avg.): 3.2 microns (avg.)

- Density (nominal)*: 64, 96, 128 et 160 kg/m3

- Tensile strength (128 kg / m3): 90 kPa

* calculated without compression

| Thickness | 13 mm | 25 mm | 38 mm | 50 mm |

| Width | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) |

| 610 mm | 14.64 | 7.32 | 5.00 | 3.66 |

| 1000 mm | 14.64 | 7.32 | 5.00 | 3.66 |

Bulk fibers

Made from a spun and blown technique, the bulk fiber has a fluffy, choppy and fluffy appearance. It is composed of calcium, magnesium and silicate with a low thermal conductivity which gives it very good heat resistance. Bulk fiber is a versatile material commonly used by manufacturers of insulation products and is ideally suited for conversion into vacuum cast panels, liners and form parts.

Loose fibers and biosoluble chopped fibers offer many advantages over other mineral fibers:

- Thermal and physical stability up to 1200°C

- Exceptional sound absorption properties

- Excellent wet forming characteristics

- Suitable for making textiles

- Efficient energy savings

- Base product for vacuum forming

- Manufacture of textiles, cement and other moldable mixtures

- Vacuum Casting Coatings and Shaped Parts

- Lining of chimneys and fire doors

- Covering of expansion joints

- Expansion joints in the building

- Filling or creation of expansion joints

STANDARD RANGE

- Bulk Fibers and Chopped Fibers

- Supplied in 20 kg bag

- Non-standard bags or other form of non-standard packaging can be provided on request, subject to minimum quantities.

SPECIFICATIONS (PHYSICAL PROPERTIES)

- Color: white

- Classification temperature: 1200°C

- Melting point: > 1330°C

- Fiber diameter: 3.2 microns (avg.)

| Width (mm) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) | Roll length (m) |

| 610 | 122 | 60 | 35 | 25 | 20 | 15 |

| 1000 | 380 | 1890 | 110 | 85 | 60 | 45 |

| 1 260 | 380 | 180 | 110 | 85 | 60 | 45 |

Need high temperature insulation felt?

Glass fabric

Glass fabric Glass fiber mesh

Glass fiber mesh PTFE coated glass fabrics

PTFE coated glass fabrics Caramelised glass fabrics

Caramelised glass fabrics Polyurethane-coated glass fabrics

Polyurethane-coated glass fabrics High temperature glass textiles

High temperature glass textiles Glass fabrics + aluminium lamination

Glass fabrics + aluminium lamination PVC coated glass fabrics

PVC coated glass fabrics Ecru silica Fabrics

Ecru silica Fabrics Vermiculite silica Fabrics

Vermiculite silica Fabrics Steel reinforcement (V4A) silica Fabrics

Steel reinforcement (V4A) silica Fabrics Glass needle felts

Glass needle felts Panox Welding Black® needle felts

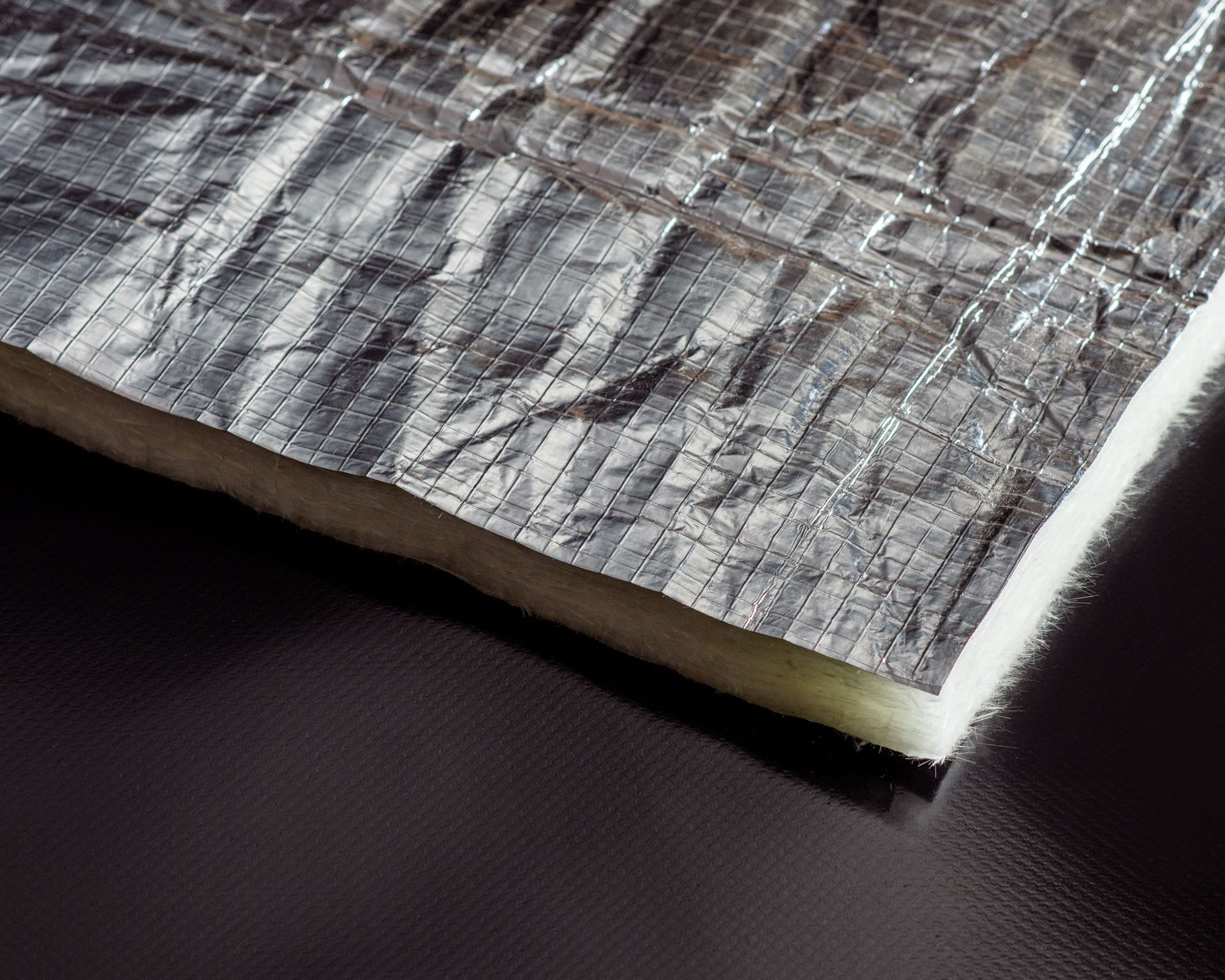

Panox Welding Black® needle felts Glass needle felts + aluminium lamination

Glass needle felts + aluminium lamination Technical fabrics

Technical fabrics Technical nets & films

Technical nets & films Protective fabrics

Protective fabrics High temperature insulating felts

High temperature insulating felts technical sewing threads, ribbons

technical sewing threads, ribbons Adhesives and technical glues

Adhesives and technical glues Passive fire protection

Passive fire protection